Чому решітковий настил і що пропонують комірчасті решітки?

В наші дні життя задає швидкі темпи будівництва і висуває підвищені вимоги до конструкційних матеріалів для зведення будівель та споруд різного призначення. Враховуючи темпи, масштаби та потреби сучасного світу, ми спостерігаємо за постійним розвитком та популярністю будівництва з металоконструкцій. Оскільки матеріали для сталевого будівництва повинні бути міцними, надійними, недорогими і відносно легкими, комірчастий настил все частіше застосовують в промисловому будівництві й цивільній архітектурі.

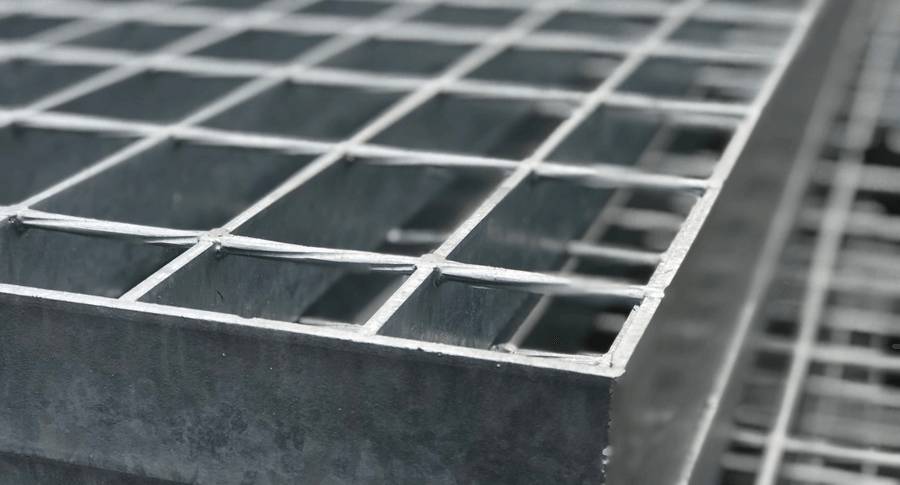

Решітковий настил – сучасний конструкційний матеріал, що використовується у будівництві в якості покриття майданчиків обслуговування, перехідних містків, галерей, трапів, а також застосувується при виготовлені різноманітних сходових маршів. Окрім того, широко використовується в якості елементів огороджень, в стелажних системах, системах поверхневого водовідведення і т.п. Решітковий настил дуже стійкий до несприятливих погодних факторів і фізичного пливу, що робить його універсальним матеріалом для застосування як всередині приміщень, так і на відкритих майданчиках. Завдяки конструктивним особливостям, решітковий настил володіє такими характеристиками як висока несуча здатність у поєднанні з легкістю, що робить його незамінним матеріалом перед основними конкурентами – просічно-витяжним та рифленим листами. Матеріал демонструє відмінні фізико-механічні властивості, що дозволяють використовувати його у всіх випадках, коли інші вироби не в змозі забезпечити належну надійність і безпеку конструкції.

Вперше решітковий настил з’явився в середині ХХ століття, практично одночасно у Європі та США. На теренах колишнього СРСР було всього дві лінії з виробництва решіткового настилу – у містах Магнітогогорську та Батайську (Росія) і називався він “Настил ВІСП” або “Батайський” настил (за назвою міста виробництва). Вказаний решітковий настил виготовлявся згідно ТУ 36-2370-82 лише у зварному виконанні. Однак, після розпаду радянського Союзу обидві лінії припинили функціонування.

У Європі та Україні решітковий настил виготовляється згідно норм DIN 24531-1, DIN 24537-1, RAL GZ-638, що забезпечує високу якість продукції європейського рівня та гарантує безпечне пересування на об’єктах промислового й цивільного будівництва.

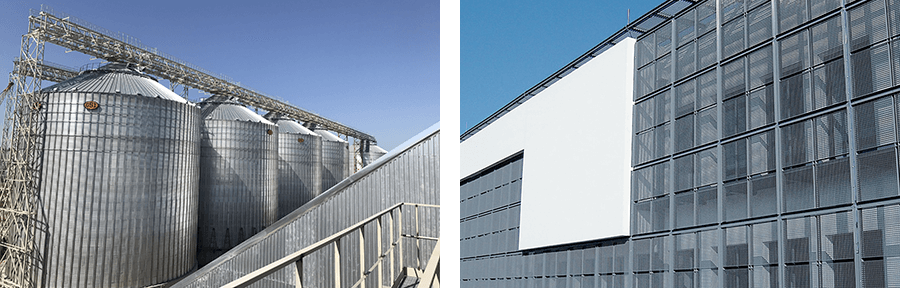

Спочатку комірчастий настил застосовувався переважно у важкій і хімічній промисловості для організації переходів, майданчиків обслуговування та їх огороджень. Однак незабаром, зварні решітки почали використовувати практично всюди, керуючись лише ідеями архітекторів, будівельників й дизайнерів. Тому й не дивно, що сьогодні решітковий настил ми можемо бачити на сучасних елеваторах, нафто-переробних заводах, автомийках, фасадах та вхідних групах ТРЦ або ж в якості елементів декору.

За технологією виготовлення комірчастий настил буває двох видів – зварний решітковий настил (SP) і пресований решітковий настил (PR). Більш детально про різницю і переваги кожного з цих типів настилу, Ви зможете прочитати у відповідних розділах нашого сайту.

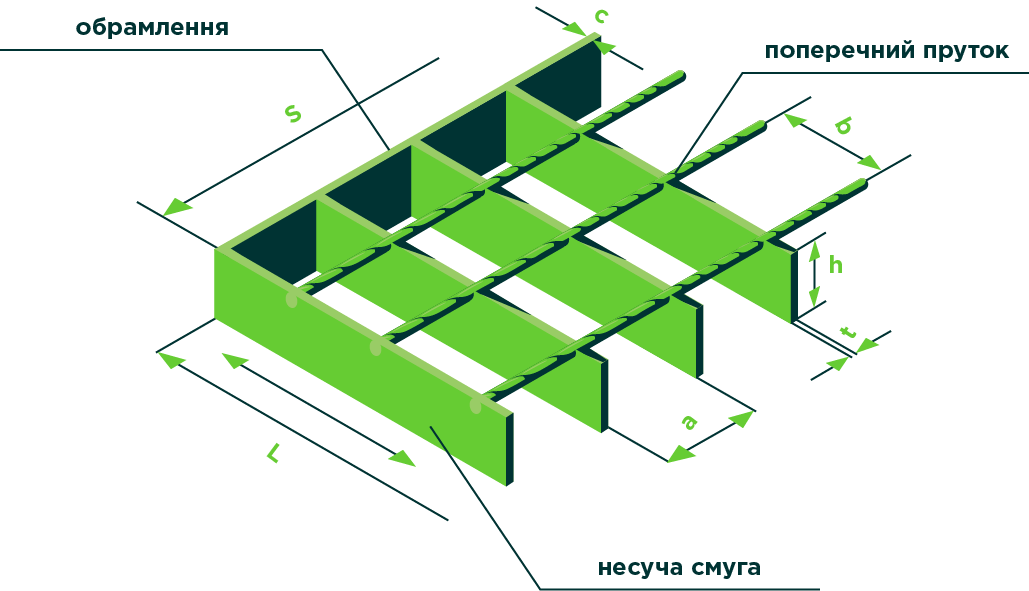

Основним елементом настилу виступають несучі смуги, які з’єднуються поперечними прутками і формують комірчасту структуру. Така структура зварних та пресованих решіток дозволяє легко й швидко змонтувати настил, навіть, у важкодоступних місцях, адже решітковий настил пропонує різноманітні типи кріплень і фіксацій. Саме зручність й універсальність під час монтажу, реалізує будівництво складних промислових об’єктів в короткі строки. Давайте детальніше розглянемо термінологію та параметри сталевого решіткового настилу:

несуча смуга – вертикально розміщені сталеві смуги, які беруть на себе основне навантаження. Розташовуються несучі смуги паралельно один до одного на відстані від опори до опори.

поперечний пруток – кручений пруток, який проходить поперек несучих смуг, і методом ковальсько-пресового зварювання з’єднують несучі смуги один з одним.

обрамлення – обрамляє торці смуг. Висота обрамлення, як правило, дорівнює висоті несучої смуги. Детальніше про типи обрамлення читайте в “Технічному довіднику“.

Основні переваги решіткового настилу перед аналогами:

- Висока несуча здатність;

- Легкість;

- Відсутність необхідності влаштування додаткових опорних конструкцій;

- Монтаж без використання зварювання;

- Широкий асортимент, який дозволяє підібрати оптимальний настил для будь-яких умов використання;

- Ціна влаштування 1 м2 покриття, що не перевищує ціну аналогів при значно кращих характеристиках.

Наша компанія на сьогоднішній день пропонує найбільший вибір решіткового настилу в Україні.