Способи кріплення решіткового настилу

Однією із суттєвих переваг решіткового настилу є простота кріплень решіток. Решітковий настил за допомогою типових кріплень, які виготовляються нашим заводом, можна закріпити практично до будь-якого елементу несучого каркасу – двотавр, швелер, кутник, профільна труба. Кріплень решіток відбувається без застосування зварювання, що дозволяє зберегти антикорозійний захист. Для монтажу необхідно лише найпростіший інструмент, який є на кожному будівництві – звичайні гайкові ключі. Для розрахунку кількості кріплень діє стандартне правило – 4 шт. на 1 м2, але не менше, ніж 4 шт. на одну решітку. Тобто, якщо решітки поставляються невеликого розміру, наприклад 700х652 мм, для надійної фіксації на таку решітку потрібно також 4 шт. кріплення. В разі, якщо на одному рівні необхідно використовувати кілька типів кріплень, на монтажних схемах вказується, які кріплення потрібно встановлювати в тому чи іншому місці. Всі типи кріплень є максимально непомітними та забезпечують комфортне та безперешкодне пересування по настилу як пішоходів так і колісної техніки.

При розробці монтажних схем для укладання решіткового настилу наші фахівці підбирають необхідні в кожному випадку типи кріплень і складають відповідну спеціфікацію, яка є невід’ємною частиною монтажної схеми. Також, за бажанням замовника, на креслення можуть бути нанесені місця установки кріплень. Таким чином, в разі замовлення решіткового настилу клієнт може бути впевнений в тому, що комплектація решіток кріпленнями буде на 100% відповідати технічному завданню.

Типи кріпленнь

Типи кріпленнь

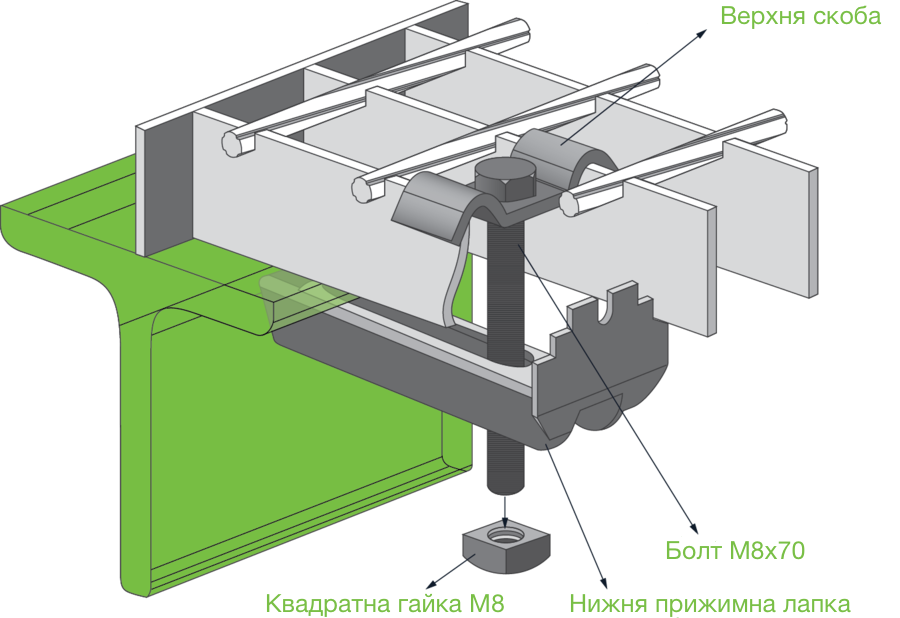

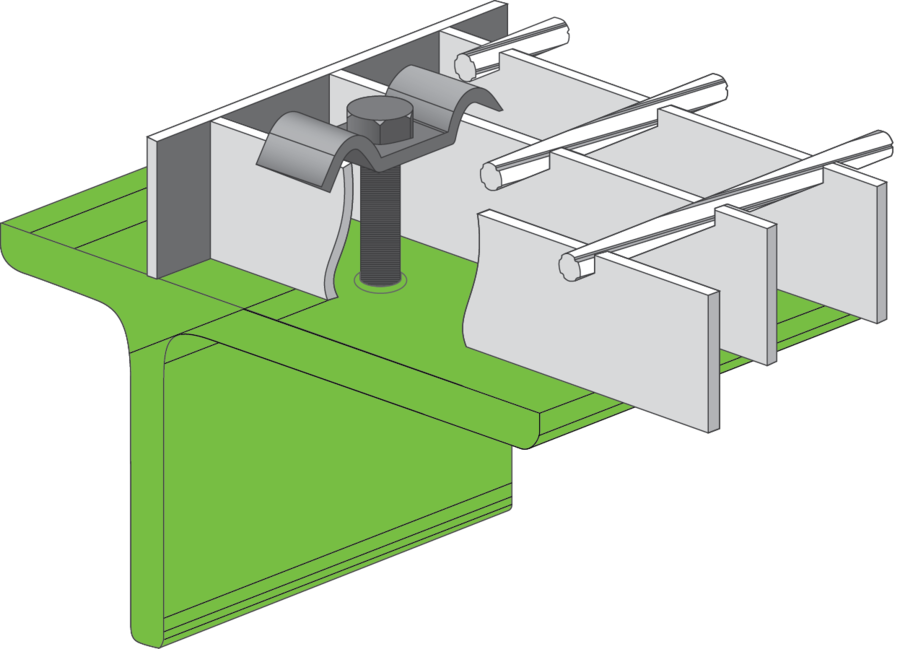

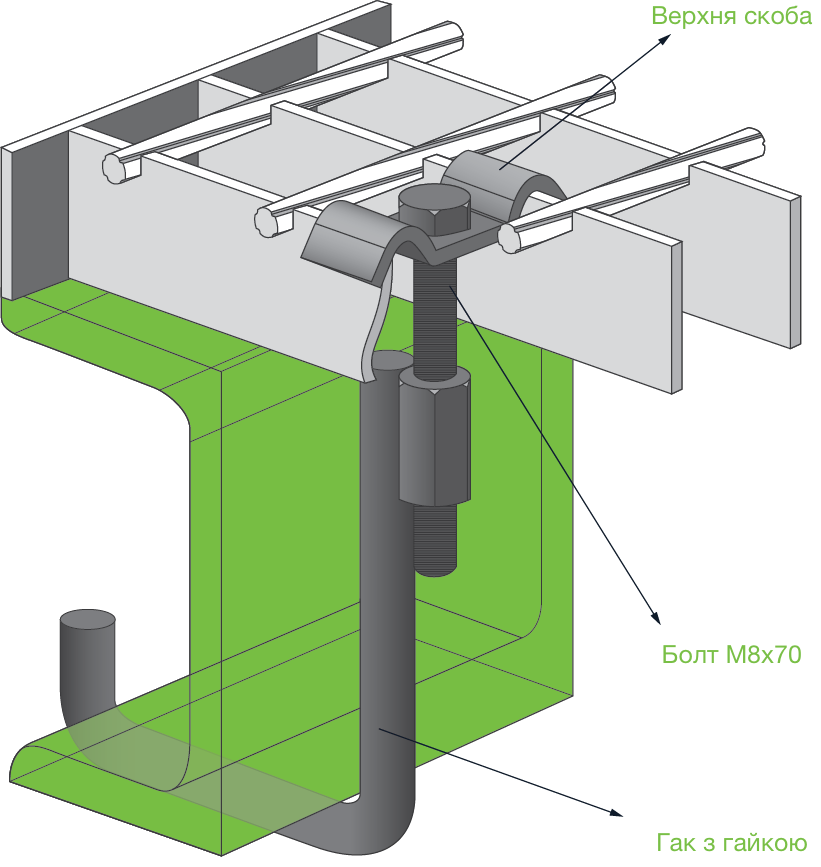

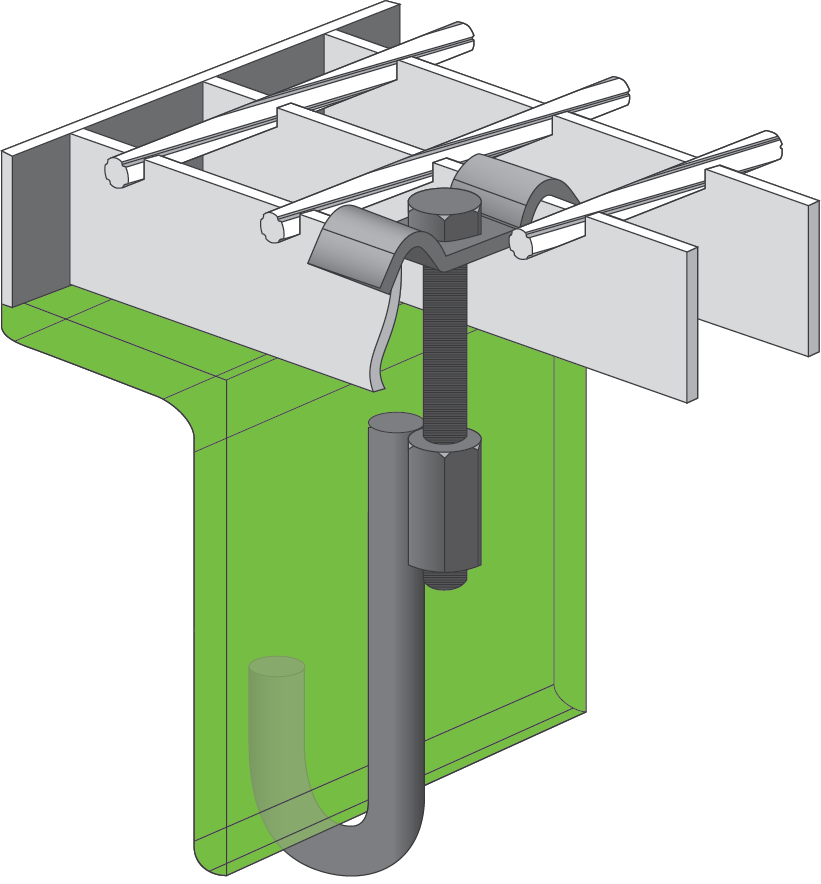

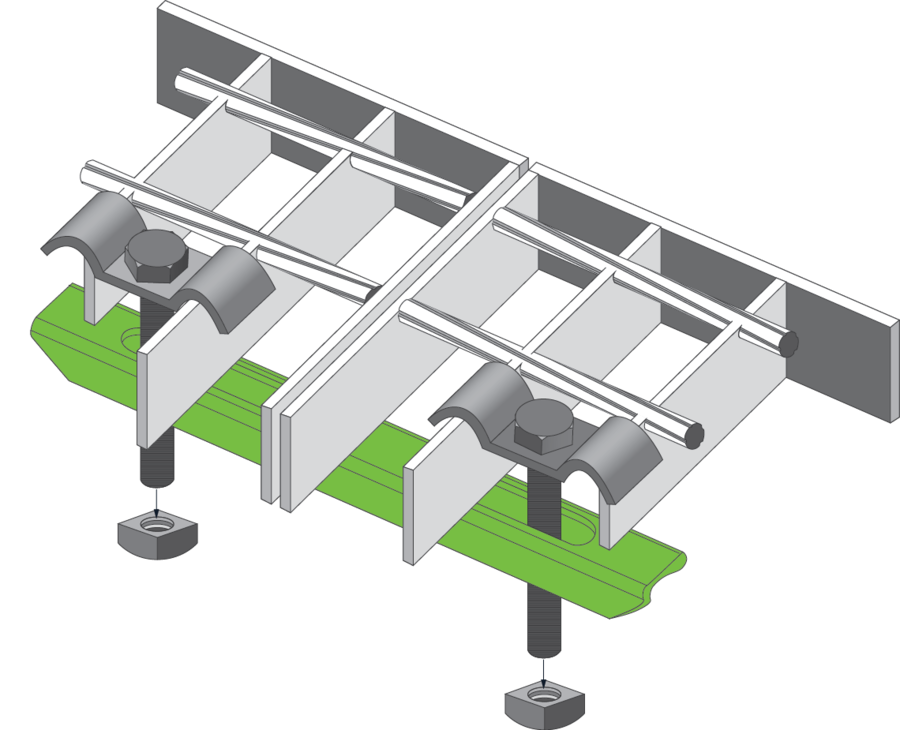

Стандартне кріплення найбільш універсальний тип кріплень, який використовується для монтажу решіткового настилу на елементи, які мають поличку – тавр, двотавр, швелер, кутник

Скоба із саморізом даний тип кріплення решіток рекомендується використовувати в разі, якщо на решітковий настил діють постійні навантаження, пов’язані з вібрацією, для запобігання самовідгвинчуванню. В комплект поставки входить скоба зі зменшеним до 7 мм діаметром отвору та саморіз відповідно до побажань замовника. Недоліком даного виду кріплень є необхідність заміни саморізів після кожного зняття решітки.

Скоба із саморізом даний тип кріплення решіток рекомендується використовувати в разі, якщо на решітковий настил діють постійні навантаження, пов’язані з вібрацією, для запобігання самовідгвинчуванню. В комплект поставки входить скоба зі зменшеним до 7 мм діаметром отвору та саморіз відповідно до побажань замовника. Недоліком даного виду кріплень є необхідність заміни саморізів після кожного зняття решітки.

В разі, якщо на одному рівні необхідно використовувати кілька типів кріплень, на монтажних схемах вказується, які кріплення потрібно встановлювати в тому чи іншому місці.

Всі типи кріплень є максимально непомітними та забезпечують комфортне та безперешкодне пересування по настилу як пішоходів так і колісної техніки.

Затиск для зєднання решіток спеціальний тип кріплення для зєднання сусідніх решіток. Цей тип кріплення не зєднує решітку з несучим каркасом, а лише обєднує решітки, що розміщені поряд і таким чином перетворює окремі решітки в суцільний настил. Це унеможливлює зісковзування решіток з каркасу, а також нівелює можливі перепади висот між сусідніми решітками у випадках, коли на одну з них діє велике навантаження, а на іншу ні. Це може відбуватись, наприклад, при переміщення транспортного візка по решітках.

Кріплення для сходинок

Кріплення сходинок до косоурів відбувається за допомогою звичайних болтів з гайками та шайбами. В стандартному варіанті постачаються гарячеоцинковані болти М8х35.